| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

Model No.: 850

Machine Make Corrugated Sheet Steel

Machine Make Corrugated Sheet Steel can produce various of steel roof and wall panel, which is single layer roof roll forming machine. it is a new building materials, the products are widely used as the roof and wall of factory, warehouse, garage, gymnasium, exhibition center, cinema, theatre, etc. It has many advantages, such as easy installation, short building period, beauty, light weight but high strength. We know well the requirements of customers from different countries.We have an excellent design and sale team, our engineers can design cold roll forming machine according to customers' requirement. Our sales will supply you best service including pre-sale and after sale service. We will try our best to help you to fulfill your requirement.

Specifications of Steel Single Layer Roof Roll Forming Machine:

Thickness of material: 0.2-0.8mm

Feeding width: 1000mm

Effective width: 850mm

Main structure:300H steel

Wall plate: 14mm

Diameter of shaft: Ф70 solid

Electric motor power: 3KW

Reducer: 4# cycloid reducer

Roller: 11-18rows

Forming speed: 8-12m/min

Material of Rollers: Carbon Structural Steel Hard chromium Plating on the surface

Cutting type: Hydraulic shearing

Motor: 380V, 50HZ/3 phase

Electrical part:CHINT,Delixi

Hydraulic motor: 3KW

Tail cutting material: Delta PLC-14ES

Delivery: 30 days after receipt of advance payment

Package: Plastic packing and nude in the container

Payment Term: T/T, L/C, Trade assurance

Warranty: Warranty: 12 months limited warranty

roll forming machine price is competitive.

The pro

Images:

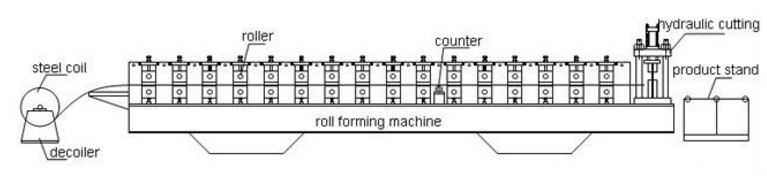

Produce process flow

Components

1. Cutting Mechanism

Roll forming machine adopts hydraulic drive and automatic location to decide the dimention and cut the target products. Match equipment : one set of cutting tool, one hydraulic tank ,one cutter machine. Stop to cut , Post cut

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job. Match equipment: a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes and two sets of electromagnetism valves.

It adopts Taida PLC to control(can make as your requirement). The target piece length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one.

5. Manual un-coiler

6. Recieving table

Main framework adopts welded steel and supported roller, and used for transmit and collect the finished products.

Packing&shippment

Contact

Any interest, please feel free to contact with us.

Product Categories : Roll Forming Machine > Single Layer Roof Roll Forming Machine